Specifications

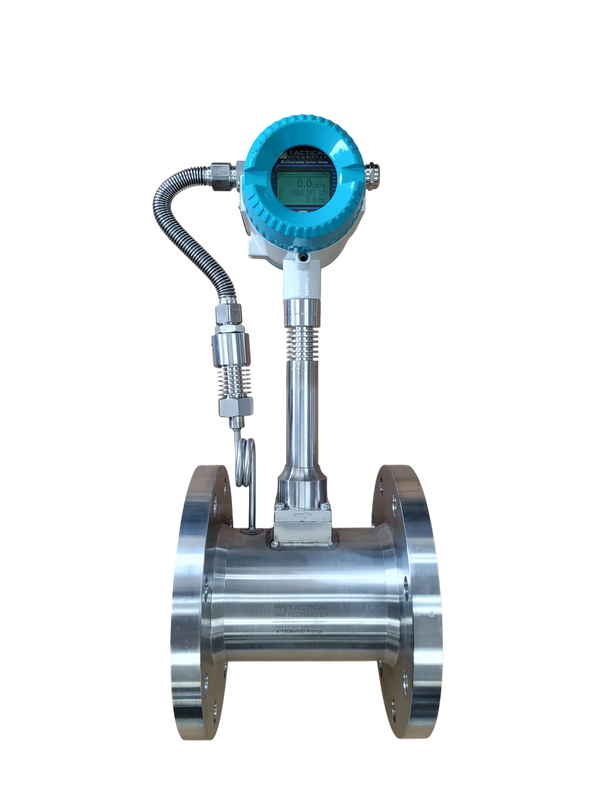

Multivariable Vortex Flow Meter Specifications

- Wetted Materials: 304 SS

- Flow Range:

- Liquid: 0.5 fps - 33 fps.

- Gas: Large Pipes 5 fps - 213 fps, Small Pipes 13 fps - 213 fps.

- Steam: Large Pipes 5 fps - 230 fps, Small Pipes 13 fps - 230 fps.

- Accuracy: +/- 1% of reading

- Repeatability: +/- 0.05% of reading

- Pipe Size:

- Inline: 1/2" to 4" 150# ANSI Flange Connections, Up to 12" available custom.

- Insertion: 8" to 72"

- LCD Display

- Temperature Accuracy +/- 1 Deg C

- Temperature:

- Gas: -40°F (-40°C) to 482°F (250°C)

- Std Temp Liquid: -40°F (-40°C) to 662°F (350°C)

- High Temp Liquid: -40°F (-40°C) to 626°F (330°C)[Add $450]

- Ambient: -40°F (-40°C) to 131°F (55°C)

- Power Requirement: 24 VDC, 15 Watts maximum;

- 3.6 VDC Lithium C Size battery for intrinsic safety mode. Has LCD Display but no 4-20 or ModBus

- Output signals: Modbus RTU, 4–20 mA, and 0-1.0 KHz for flow rate indication

- Digital communications: Modbus RTU

- Max Pressure: 1.6 MPa, 230 PSIG. (Custom up to 4.0 MPa 580 PSIG)

- Display: Flow rate, Total flow, Temperature, and Pressure

- Wiring connection to enclosure size: M20 x 1.5

- Factory Final QC Test Certificate

- Integral Electronics

- Electronics Enclosure: NEMA 4X / IP67

Instructions

TFM Vortex Series VT-222 Manual

TFM Vortex Series VT-201 Manual

Flow Range

The Vortex meter has different minimum and maximum flow velocities it can measure based on the fluid type and meter size. Please note the values below for proper sizing of your meter.

- Steam:

- Gas:

- Liquid:

Nominal Vortex Flow Rates for Air

The table below gives the minimum, nominal, and maximum velocities for the Vortex Meter for gases to assist users familiar with Thermal Mass Flow Meter sizing guides relative to air, with a density of 0.075 lb/ft^3 for reference. As the pressure goes up the flows go up as well. For example, if the pressure is DOUBLED, so too does the mass flow. Download chart below here:

IMPORTANT Note to Thermal Mass Flow Meter users...

Did you know that Multivariable Vortex Flow Meters offer a significant advantage over Thermal Mass Flow Meters when it is not necessary to measure ultra low or ultra high flows?

Did you know that a Multivariable Vortex Meter is not affected by gas composition? This means you can change gas composition and STILL report the proper Mass Flow! Why utilize a Gas Chromatograph to determine gas composition to correct your Thermal Mass Flow Meter measurement? If you need ultra low flows it makes sense but if your minimum flows are within the measuring range of a Vortex meter then consider a Multivariable Vortex Mass Flow Meter.

As well, it is important to note that Thermal Mass Flow Meters are quite sensitive to moisture in the flow stream. The most common undesirable effect is momentary flow spikes that can upset your control system. Vortex Meters, on the other hand are NOT sensitive to moisture in the flow stream and offer a significant advantage over Thermal Mass Flow Meters if such spikes are determined to be undesirable.

Have you ever have problems with temperature swings causing your Thermal Mass Flow meter to over or under report the flow measurement? The Multivariable Vortex Mass Flow Meter does not exhibit these symptoms simply because the vortex shedding velocity is not a function of temperature or pressure. And, with the Multivariable Vortex Meters built in Pressure and Temperature sensors you can get true Mass Flow, Pressure, AND Temperature and even gather Volume flow on those rare occasions when deemed necessary. And, you have a true pressure measurement as well as the Mass Flow and temperature. All at a price very competitive with Thermal Mass Flow Meters.

HOWEVER, if you DO need very low or very high flows we suggest the use of Thermal Mass Flow Meters. As well, Thermal Mass Flow Meters are ideal as "Insertion Meters" as they are small and if, and ONLY if, there is no moisture, or gas composition changes then the Thermal Mass Flow Meter is a very good choice. Otherwise, the Vortex is the best choice as it has NO sensitivity to the gas composition or droplets or hydrocarbon particulate.

Refer to the chart above for the minimum and maximum flows for the Vortex Mass Flow Meter. Refer to the minimum and maximum velocities for the fluid you wish to use to see if a vortex meter is a good choice. If your flow is within the velocity range of the Vortex meter AND you have moisture or any change in gas composition then a Vortex meter is a better choice over the Thermal Mass Flow Meter.

Important Note: Vortex Flow Meters want to be rigidly mounted or isolated from vibration to prevent the vibrating energy to be transmitted to the Vortex Piezo Sensors. This can be accomplished by rigid mounts to a solid base or good vibration isolation.

How to use button interface and ModBus RTU video:To get the most out of the video open the link below and print out the document or open it in another window.

Display

|

See the video below to see how to use the buttons on the display within the enclosure.

Features LARGE LCD display, shows the Flow Rate, Total Flow, Temperature, and Pressure in user selectable units.

Menu

Vortex VT-210 Meter Menu Details

MENU 22

Q Unit >> l/m

Q Mode >> Qvw actual (We are measuring volume flow....)

Q Factor >> 2121.47 Do Not Change (This is stamped on the side of the meter)

Density >> 875 kg/m3 (Water is 1000)

Q20mA >> 250 (FULL SCALE... If your meter is 250 l/m)

Q Cut-Zero % >> 5

Q Up Al >> 250 to turn the alarm on at 100%

Q Dn Al >> 25 to turn the alarm at 10% flow

Damp S >> 6

Comm Address >> 0

Clear Q >> Clears Totalizer, Password = 70

MENU 33

Language >> English

Pulse Type >> F_adj

Pulse Factor >> 0.01

Comm Param >> 9600, No

Comm Switch >> ON

P_display >> MEASURE

Set Pc >> 0

P0-Ref >> 101.3KPa

T_display >> MEASURE

Set Tc >> 20 Deg C

T-TYPE >> Pt=100

Tn >> 20 Deg C

Environ-T >> -20 Deg C (-10 C is fine if you do not get them cold.)

Q-adj >> DO NOT change this setting

MENU 44

Signal-TYPE >> LF: DN40-500 Lqd

Gain >> G=9

VPP limit >> 100mV

Fre-Range >> 11=34-850Hz

Work Type >> Digital

an-noise TYPE >> ANS

Signal-Adj-Set >> FIlter 10 or OFF

50Hz Cut >> ON

K-LINE ADJ >> DO NOT change this setting

Dimensions

How to Invoke Variable K-Factors in the Tactical Flow Meter Vortex Flow Meter:

Screen 33 Instructions are for advanced users only. Do NOT invoke this screen on your meter unless you have a pressing need. It is important to note all settings PRIOR to making any changes. Note: Left button HOLD gets you OUT of menus.

See example spreadsheet here

Before exiting ensure you SAVE the data and CONFIRM the % numbers are ever increasing in from element 0 to element 4. The Correction ratio must be between 0.8 and 1.2.

Where to get Power Supplies, Gaskets, Nuts and Bolts Link

Important Note: Vortex Flow Meters want to be rigidly mounted or isolated from vibration to prevent the vibrating energy to be transmitted to the Vortex Piezo Sensors. This can be accomplished by rigid mounts to a solid base or good vibration isolation. We show some settings below as examples for your study. The video above shows how to enter the configuration modes.

Typical Vortex Meter Settings for reading Volume Flow for Liquids with a Full Scale of 250 l/m for a fluid with a density of 875 kg/m3 for a 3" Vortex Meter where the vortex frequency is from 34-850 Hz.

3D Files

Link to Copyrighted Wafer Meter STEP Files here 3',4",6" & 10" SIZE ANSI 150# Wafer

Link to Copyrighted FLANGED Meter STEP Files here from 0.5 to 2.5" ANSI 150# Flange

Link to Copyrighted FLANGED Meter STEP Files here from 3 to 12" ANSI 150# Flange

Cut Sheets

Videos

Video showing User Interface for TacticalFlowMeter.com VT-222 Series Multivariable Vortex Mass Flow Meter:

How to use ModBus Poll to read the totalizer in a Type 2 Vortex Meter.

Video showing how to use the spreadsheet above and the Front Panel Interface with Menu 33:

How to verify and set up Full Scale and Units:

Refer to the Vortex Meter LCD Interface Video above for overview and introduction to using buttons.